Cut Size Sheeter

FROM REEL TO SHEETS IN FINISHED FORMAT

CSS, our brand-new cut-size sheeter, is the ultimate solution realized by our technicians and benefits from their 20+ years’ experience in the paper converting industry and expertise in mechanic and electronic industry. CSS completes our line of paper converting roll-to-sheet machines.

CSS series sheeters have an innovative production system ensuring the output of finished products directly from reels (one or two). Product size is customizable according to customer’s specific needs without recurring to linear cutters.

The simultaneous cutting of two paper reels, printed with double register control, allows for combined operations that traditionally required two different types of sheeters: a cross cutter and a linear cutter. This process enables a higher production speed (up to 500 cuts/min.), requires less operators and reduce the cost of the finished product.

The unwinders are equipped with a brake system ensuring constant tension on the reels both in the acceleration/deceleration and variation of the reel diameter phases.

CSS is built with vertical blades to divide the reels up to 5 parts and can be also equipped with more blades for side trimming.

Stepper motors in the cut assembly provide for automatic adjustment of the paper size. CSS can reach very high cut speed (up to 500 cuts/min.) CSS works well with a wide range of materials: tissue paper, wrapping and gift paper, coupled paper, PE, PET, BOPP etc. (14-100 g/sm) A series of conveyor belts moves the sheets to the stacker system, equipped with an automatic ream changing system.

The reams containing the selected quantity of sheets (50-1000) can be moved from the conveyor belts to the boxes or onto trays, and transferred to an automatic packing system (shrink-wrapping, taping, labelling and palletizing).

CSS has a 10.4” color touchscreen control panel housed in a rotating support aluminium arm. Operators can manually set work parameters, display production data, save previous programs, make diagnosis, maintenance and repair operations. Automation is integrated with a web-based diagnostic system, remotely controlled.

CSS series sheeters have an innovative production system ensuring the output of finished products directly from reels (one or two). Product size is customizable according to customer’s specific needs without recurring to linear cutters.

The simultaneous cutting of two paper reels, printed with double register control, allows for combined operations that traditionally required two different types of sheeters: a cross cutter and a linear cutter. This process enables a higher production speed (up to 500 cuts/min.), requires less operators and reduce the cost of the finished product.

The unwinders are equipped with a brake system ensuring constant tension on the reels both in the acceleration/deceleration and variation of the reel diameter phases.

CSS is built with vertical blades to divide the reels up to 5 parts and can be also equipped with more blades for side trimming.

Stepper motors in the cut assembly provide for automatic adjustment of the paper size. CSS can reach very high cut speed (up to 500 cuts/min.) CSS works well with a wide range of materials: tissue paper, wrapping and gift paper, coupled paper, PE, PET, BOPP etc. (14-100 g/sm) A series of conveyor belts moves the sheets to the stacker system, equipped with an automatic ream changing system.

The reams containing the selected quantity of sheets (50-1000) can be moved from the conveyor belts to the boxes or onto trays, and transferred to an automatic packing system (shrink-wrapping, taping, labelling and palletizing).

CSS has a 10.4” color touchscreen control panel housed in a rotating support aluminium arm. Operators can manually set work parameters, display production data, save previous programs, make diagnosis, maintenance and repair operations. Automation is integrated with a web-based diagnostic system, remotely controlled.

MATERIALS

CSS works well with a wide range of materials: tissue paper, wrapping and gift paper, coupled paper, PE, PET, BOPP etc. (14-60 g/sm)

MAIN FEATURES

Motors

7 brushless motors and drives in electric axis between them

Movements

10 pneumatic axis controlled by an HMI panel

Check systems

Double register control, performed by a sensor for mark detection

Controls

10.4” color touchscreen panel, with database to manage cut programs

Cut

Motor-actioned cut assembly to divide the reel up to 5 parts

Stacking

Automatic ream unloading by motorized belts

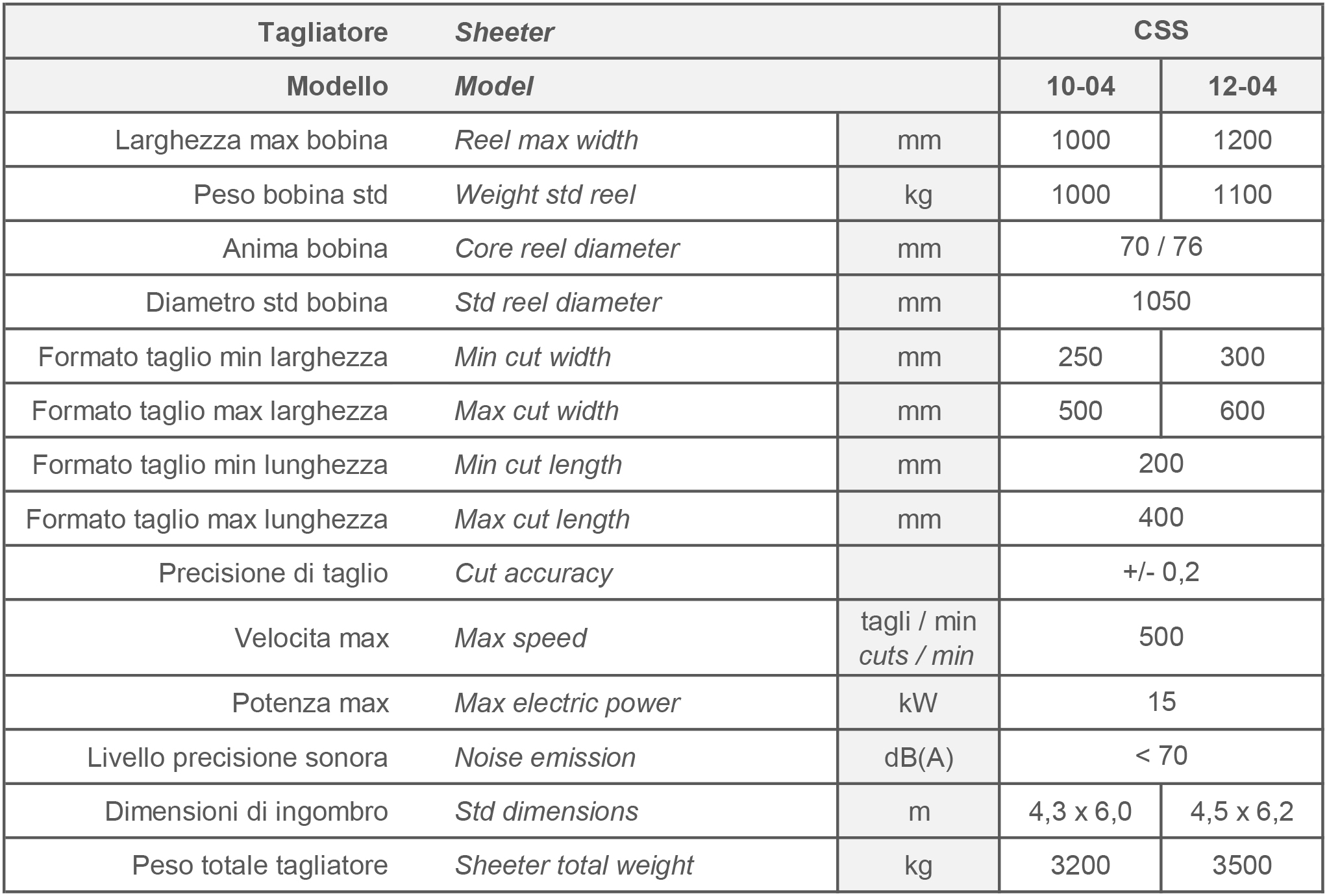

TECHNICAL DATA

GALLERY